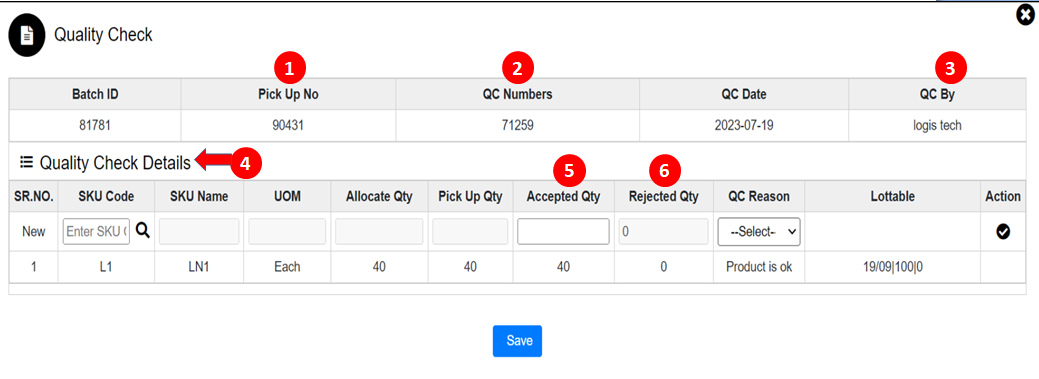

Quality Check

Outward–Quality Check

After picking the order next step is a quality check in this process user will check the quality of the material and whether the material is good or damaged. If the material is damaged then the user needs to mention the quantity in the accepted quantity field then as per the order quantity system will calculate the rejected quantity.

E.g.: Order quantity:50

Accepted qty: 40 then the system will calculate rejected qty as 10.

for this step, the user needs to click on the red button which is present in picking after that system will open the Quality check page.

- Batch Id: After creating allocation batch system will generate the batch id & that batch id will display in batch id of QC page.

- Pick Up No : After completing picking system will generate pick up no & that number will display in batch id of QC page

- QC number: After saving the record of QC system will generate the QC number.

- QC By: The system will display the username of who performed the QC process.

- Quality check details: in this field after selecting sku from the list sku details will bind as per field requirement.

- Accepted Qty: In accepted user will enter a quantity that is not damaged.

- Rejected Qty: Aa per order quantity system will subtract the accepted qty from the order quantity will calculate the rejected qty.

- User need to click on the action button successfully saving of sku details.

- Then for complete the quality check process user need to click on final save button.

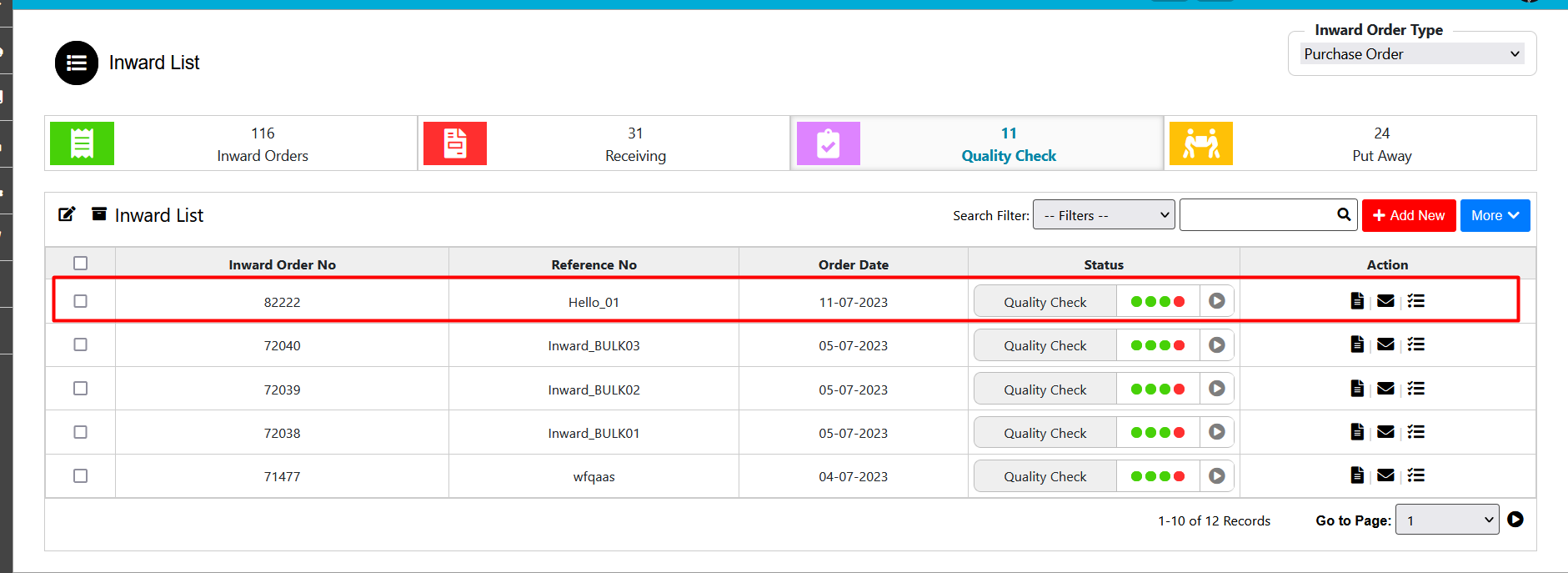

After clicking final save button the QC process will complete & the order will display in the quality check tab with status of Quality check.

Created with the Personal Edition of HelpNDoc: Easily create Web Help sites